Balsamic Vinegar of Modena Italy! Excellent and very complex product starting from its fermentation chemistry! Production is not easy but you are in the right place to get useful information.

Today we will talk about Fermentation Chemistry, another important element in the production process of this unique food in the world.

Traditional Balsamic Vinegar is a “living product”. During the very long period (25 years) of its ageing, microbiological and chemical-physical transformations of cooked must occur. The cooked must is the only ingredient.

The must is the juice of the ripe grape pulp and is composed of 75-80% of water, 15-18% of sugars and the remainder of organic acids, nitrogen substances, peptide substances, mineral substances, enzymes, vitamins and microorganisms.

The sugars which are an important component in the quality of the final product are glucose and fructose. They are present in equal parts to 50%, from their alcoholic fermentation we obtain ethyl alcohol which will transform into acetic acid.

How we have already seen in the following article https://usebalsamicvinegar.com/the-boiling-of-grape-must-as-a-key-element-for-the-balsamic-vinegar/ cooking must is the first very important phase of the transformation of the product where we obtain the concentration of sugars.

It starts at a temperature of 90/95 degrees during the first 2 or 3 hours and continues for another 8 or 12 hours at 80/85 degrees until obtaining the desired reduction and concentration of sugars (max 25/30 degrees Babo).

Balsamic Vinegar of Modena Italy: chemistry of fermentation

Let’s explain it step by step.

After cooking the must we must ferment it. Fermentation is a world that derives from the Latin “fervere”, to boil. It is used to indicate the appearance od the must during the preparation of the wine. From a strictly chemical point of view, it is an anaerobic oxidate process carried out by numerous organisms on sugars for the production of energy.

In the first part of the alcoholic fermentation, the sugar contained in the must is consumed while alcohol is produced. The initial sugar content of the 25/30° Babo cooked must drops to 16° Babo in the fermented cooked must.

Fermentation takes place thanks to two distinct strains of eukaryotic single-cell microorganisms already present in the surface of the grapes and the air the saccharomycetes and the zygosaccaromycetes (you can buy them freeze-dried).

In this case, the main difference that distinguishes them is that the saccharomycetes prefer musts with Babo gradation lower than 32° and a high presence of fructose. The zygosaccaromycetes prefer musts with a gradation higher than 32° Babo with a high concentration of glucose.

What is better for the Traditional Balsamic Vinegar?

The ideal product is a must with a high presence of fructose because glucose has a high risk of crystallization, a process not appreciated in the production of Traditional.

Fermentation takes place with some favourable conditions: constant environmental temperatures from 18 to 25 degrees C, presence of nitrogenous substances in the must, not excessive osmotic concentration, must acidity not higher than 2.5% or 3%

Acetic fermentation

Another indispensable step for the production of the Traditional is the transformation from alcoholic fermentation to acetic fermentation of the must.

This transformation occurs thanks to the oxidation of ethanol catalyzed by some species of Aceto Bacteria. Single-celled prokaryotic organisms are aerobic-obliged bacteria capable of fixing oxygen in quantities equal to 500 times their weight. They create membranes of varying thickness on the surface and are sometimes dispersed in the mass, giving the liquid turbidity.

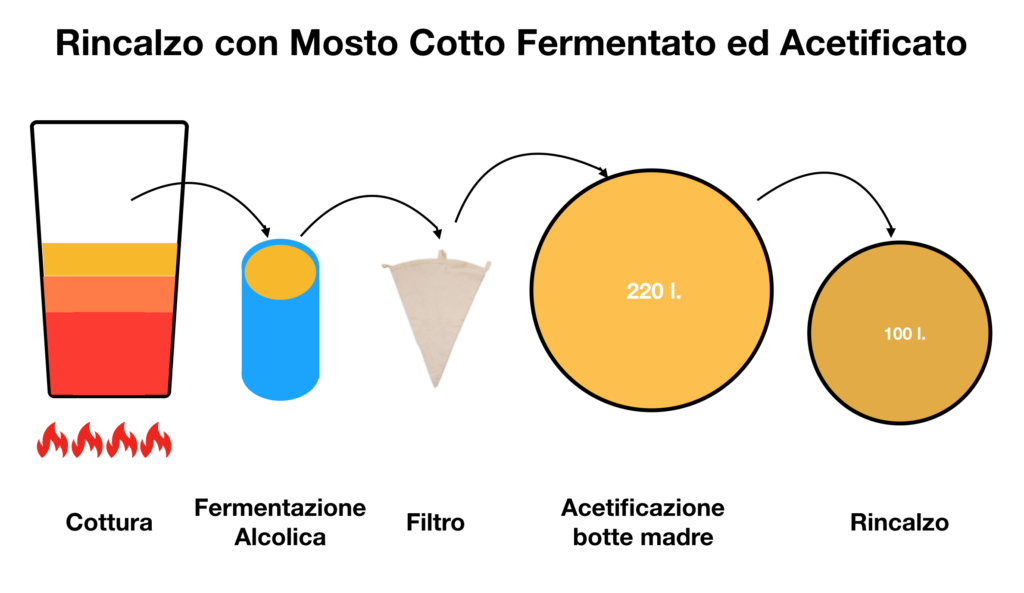

How to make the cooked must acetate?

To obtain acetification, it is necessary to gradually add the cooked must into the acetified cooked must present in the Mother Barrel until obtaining a maximum alcohol content of 2% and an acetic content of 7/8%.

The cooked must is usually added when the liquid present in the Mother Barrel corresponds to about 50% of the total volume of the barrel and the surface area is in contact with air.

The adding is performed by introducing a small quantity of fermented must with a small tube. It is important to be careful not to break the veil of fermentation present and constantly check the acidity values.

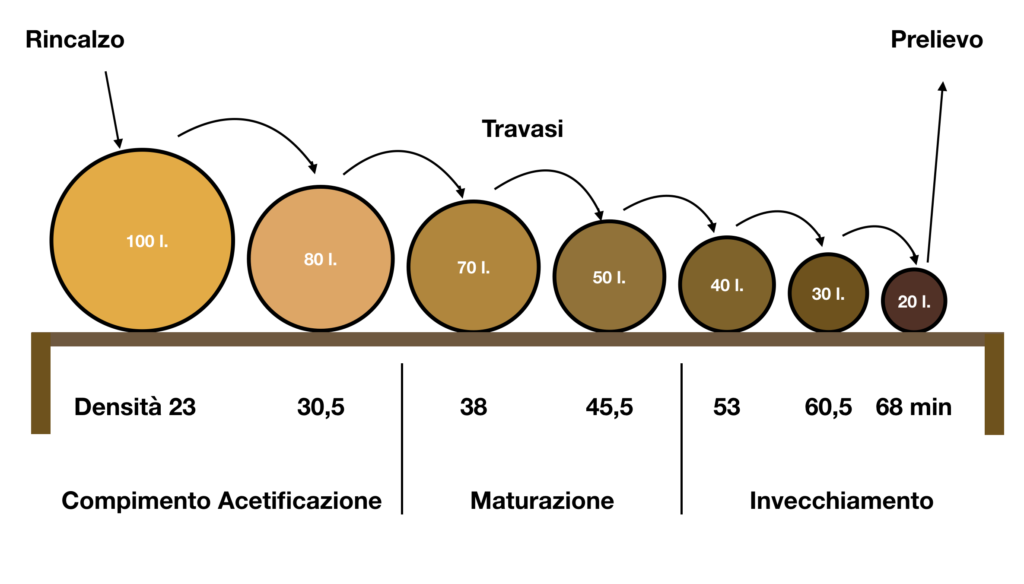

These are the initial stages of the production of Traditional Balsamic Vinegar of Modena. They are repeated year after year and we will obtain the Acetified Cooked Must that we will use to carry out the operations of sampling, decanting and pressing.

We will repeat these steps over time and they will determine the well-being of the battery and the quality of the product.

Balsamic Vinegar of Modena Italy: maturation and ageing

The long ageing process is characterized by different phases of biological activities. The microbial vitality (with different times in the smaller barrels) is destined to become extinct and transform itself into the autolysis of the microorganisms that no longer viable pour cellular enzymes.

Maturation

At least 12 years. It is the phase during which proteins are demolished into their main constituents (amino acids, nucleic acids and bases).

Complex sugars are transformed into simple sugars and fatty substances into fatty acids. After decanting, bacterial autolysis is renewed every year, forming esters (indispensable substances that create the organoleptic perception of smells and flavours).

It is in this stage that the aromas that characterized the ABTM begin to appear in the vinegar.

Ageing

During ageing, 25 years, with the cessation of enzymatic activity and with the fundamental presence of oxygen, very important chemical-physical phenomena develop.

These reactions do not stop even after 50 years and have not reached their limit.

The substances in the smallest barrels trigger acetification, esterification, resinification, oxidation of the phenolic compounds which will be essential for the harmonious refinement of the organoleptic characteristics.

There is also the very slow formation of colloids which give Traditional Balsamic Vinegar its characteristic viscosity.

The product obtains its maximum peculiar quality, its structure the flavours and aromas reach the apex and make its characters inimitable.

Unique food excellence in the world.

Balsamic Vinegar ofhttps://usebalsamicvinegar.com/how-to-make-balsamic-preparing-the-barrels/ Modena Italy?

You can find out by reading the various linked articles and find out how to use it with our tasty recipes.

Greeting from Modena.

Use Balsamic Vinegar All you need to know about Balsamic Vinegar of Modena

Use Balsamic Vinegar All you need to know about Balsamic Vinegar of Modena